To return to the Travel Blog Start Page

BACKGROUND

I believe this happened in 2009. Might be plus or minus a year, though. My memory is failing me as I get older. Also, I only provide the company's name for context. I was not paid for this blog, but they did provide everything for the trip, so it is the least I can do to mention them.

But, I was dating a woman at this time, who I later married. We liked to travel together. And one day, I was offered a trip to Honduras to see how Rocky Patel Cigars are produced. I called her and said we had to decide "today". She said yes, and then all I had to do was buy flights. So the two of us, along with a friend that lived near by, booked flights and within a week we were flying into Tegucigalpa, Honduras 🇭🇳.

Now, I didn't know this at the time, but the TGU airport is (or maybe "was") always listed in the Top 20 most dangerous approaches for landing list. But the landing for us was quite enjoyable, and I only found out later when the algorithm showed me a Yooz Toobz video of a landing in Tegucigalpa. I believe the airport may have been moved since then, so hopefully if you are going now, it will be a less stressful approach for the pilots. I think my future bride may not have said "yes" to the trip so quickly if she had known this.

We had a great time. See some of the stories below.

Roadside Images

I would love to know the story about a US Mail truck being in Honduras 🇭🇳. Maybe sold at auction, without removing the letters? Maybe delivering US Mail to somewhere south of Honduras 🇭🇳? Any ideas?

We ate lunch here since we were so far from the Spanish Colonial house. Notice the unrefrigerated meats 🍖 and fresh bananas 🍌. I love the simplicity and the lunch was delicious. Don't be afraid to try new things!

Accomodations

The Spanish Colonial house we stayed in and tour bus that hauled us everywhere. Notice how the bus blocks the entrance? There's a reason for that.

Nimesh Patel (Rocky's brother or cousin) enjoying a couple of sticks while explaining the low-down of the house and hearing what we are interested in. Super sharp person and made really awesome suggestions for each person to try the types of cigars that they liked.

The courtyard of the Spanish Colonial house that the Patel brothers rent for these tours. Included is the lovely chef who made every fabulous meal in proper Central American fashion.

Our friend getting a round of beers 🍻. There were three choices: blue, green, or red. But in the hot, steamy Honduran 🇭🇳 weather, cold beers were absolutely delicious.

The private bedroom that my future wife and I shared. The door on the right side is a toilet room with entry from the other room, shown below.

This is where all the gentlemen who were traveling without a significant other stayed. I am so happy I convinced my significant other to go with me. 😄

Making Cigars

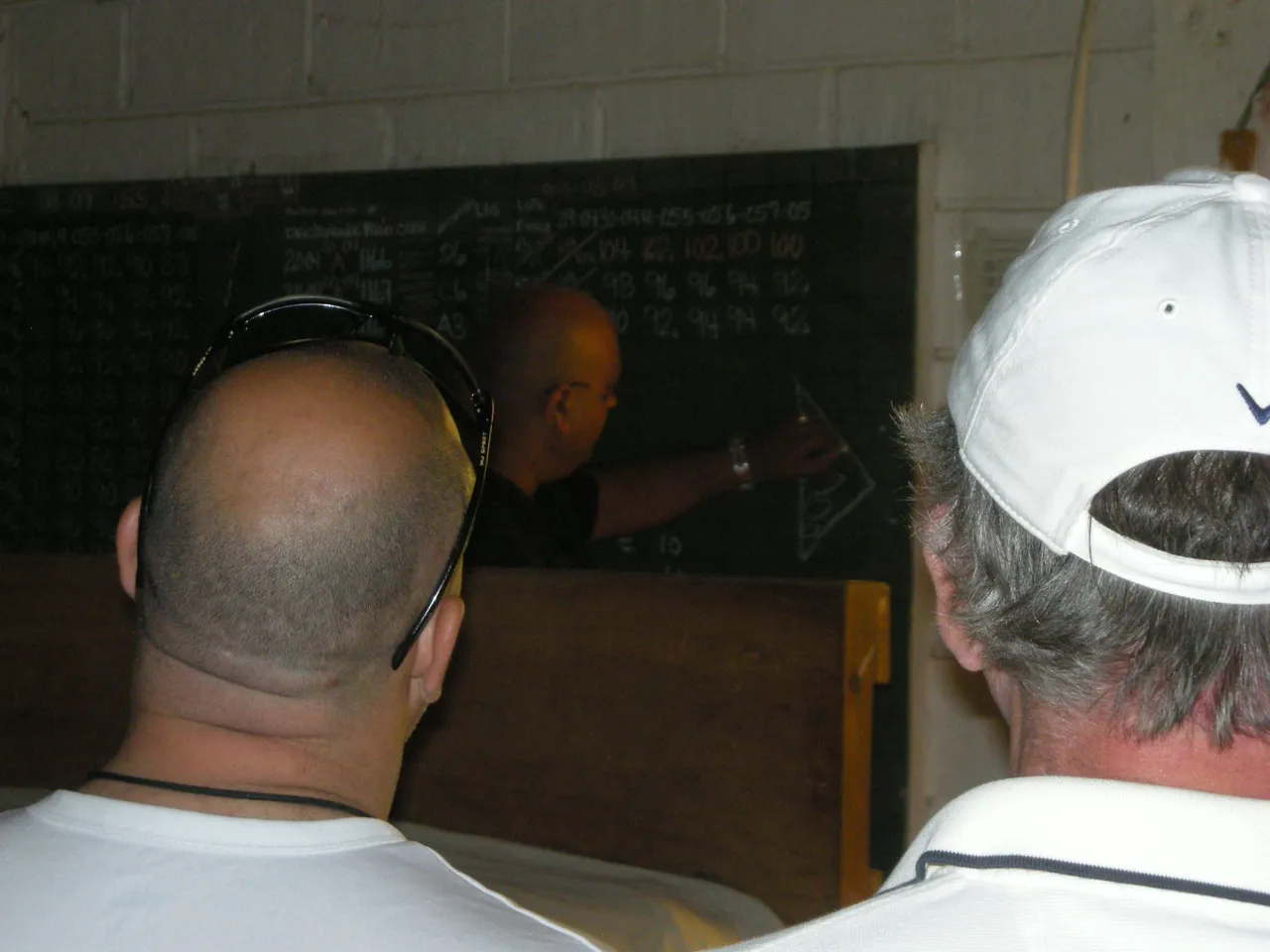

Classroom time.

Just enough info to know how it is done, but not enough detail to start my own business.

We were there late in the season, and this was expected to be the last crop of tobacco for the year. These plants were fairly immature still, as they can reach over 2 meters (6 feet) high when fully grown.

Once the leaves are harvested, they are hung on sticks in drying barns. Some of our group helping the real workers hang the sticks of tobacco leaves. One fellow from our group even climbed up into the top of the barn. He said the aroma was like nirvana.

A slightly earlier pick of leaves, starting to turn brown.

An even earlier pick of leaves that are almost ready for boxing.

The drying sticks are brought into the boxing facility. The leaves are sorted based on condition and color, then boxed into an appropriate box. Damaged leaves become filler while the perfect leaves go on the finest outer wrapper layers.

I had the honor to meet Mr. Plasencia. This gentleman is one of the hardest working, relentless people I have ever met. He had to rebuild his business twice, and still came out as one of the most premier tobacco growers in Central America. His story is worth a read.

The boxes and crates of tobacco are shipped from Mr. Plasencia to a rolling facility. This is the unloading and inventory area.

Another kind of tobacco. (I forget the details, though.)

Several other kinds of tobacco in the background, with the current brown burlap bags going to the production room. These guys work so hard. This is one of many reasons why a quality cigar is expensive, and worth every bit of money.

Preparation racks, I believe to get the tobacco to just the right moisture content to make the leaves flexible, but not tear. These would be final wrapper leaves only.

Stacks of racks getting ready for the rolling room.

Chopped filler.

Strand filler.

Sorting before Rolling

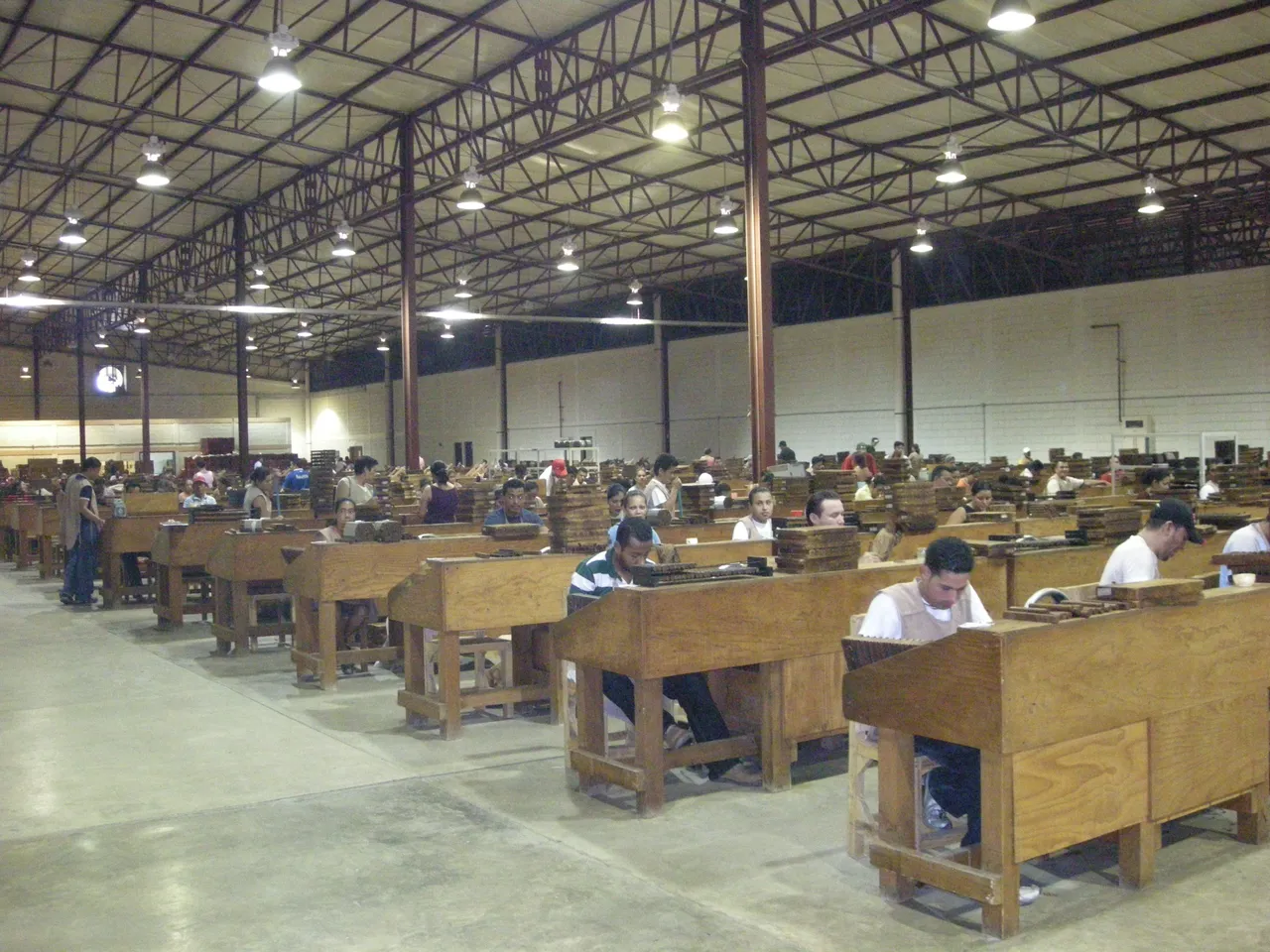

The tobacco comes from inventory for the daily production plan. It is then sorted into large bundles, essentially the recipe for that day's production.

Maduro (aged) tobacco. It is my favorite, so rich and sweet tasting.

Rolling

The fillers are combined and checked with an anemometer for draw, or how hard it is to suck air through the filler. Yet another quality check, making the good cigars worth the money. The people doing this work add filler to make the draw "tighter", or more resistance to air flow, until it hits the target range for pressure drop for that particular cigar.

Maduro again! Worth a special mention. I feel a little bad though because of the water leaching tobacco juices onto the rollers & sorters hands. But again, maduro cigars tend to be more expensive because of the extra aging and care to roll them.

I forget the details here, but I think it was the final sort table, where they would group cigars together for the same box that had the same color and texture. This is just another quality step that is not necessary, but makes the box that much nicer when you first open it.

Grouped for boxing.

Finished product, grouped into box-counts. I love the pigtails on these, but it is really just decoration because you cut it off to smoke the cigar. This is also why the draw test has to be done on the filler only, because the final wrapper does not have an opening to draw through.

Custom Sticks for Everyone

Toward the end of our trip, Nimesh showed us a table with a huge variety of strand filler. He had us write on a form our own custom cigar combination.

I got lucky and actually got to see the chaps rolling my cigars. They did a fine job and my cigars were a hit with my family when we got home.

Then a day or two later, the factory had pumped them all out, and we each got to take home a box of our own custom cigars.

Boxes

The boxes are a neat thing for cigars. They are useful for storing knick-knacks after you've smoked all the cigars. And I've seen purses made out of them too. This was the wood outside the box factory being prepared for production.

Production room of boxes.

Some kind of machine that I suspect would not pass US Occupational Safety Health Administration (OSHA) standards.

Buildings

I just can't remember what each of these buildings are.

Pretty sure this is the boxing plant though. Funny story here about my future bride's ability to destroy Honduran plumbing. But I'll leave it at that.

Beautiful flowering trees 🌸, nice pastel-colored buildings, and a guard with an automatic rifle. Every factory and farm we visited were equipped like this. And our keepers on the bus had pistols hidden in their belts. I felt perfectly safe, but I guess that is because the people watching over us were excellent at keeping us safe.

CONCLUSION

Shortly after this trip, there was a large political disruption in Honduras 🇭🇳. I do not know the status now as US and other western news sources have gone quiet about the state of political affairs. I would love to go again, and maybe even El Salvador 🇸🇻 and Nicaragua 🇳🇮. The countryside is so beautiful and the people seem genuine and happy, even though they have to go to work with an armed guard to protect them.

I hope the best 🏳️ for all of Honduras 🇭🇳 and its neighbors.