Clear the road! That sexy female engineer is here. The time to waste time is no more available. Now hop in and let's hit the road!

Source: Pixabay (Public domain - CCO licensed)

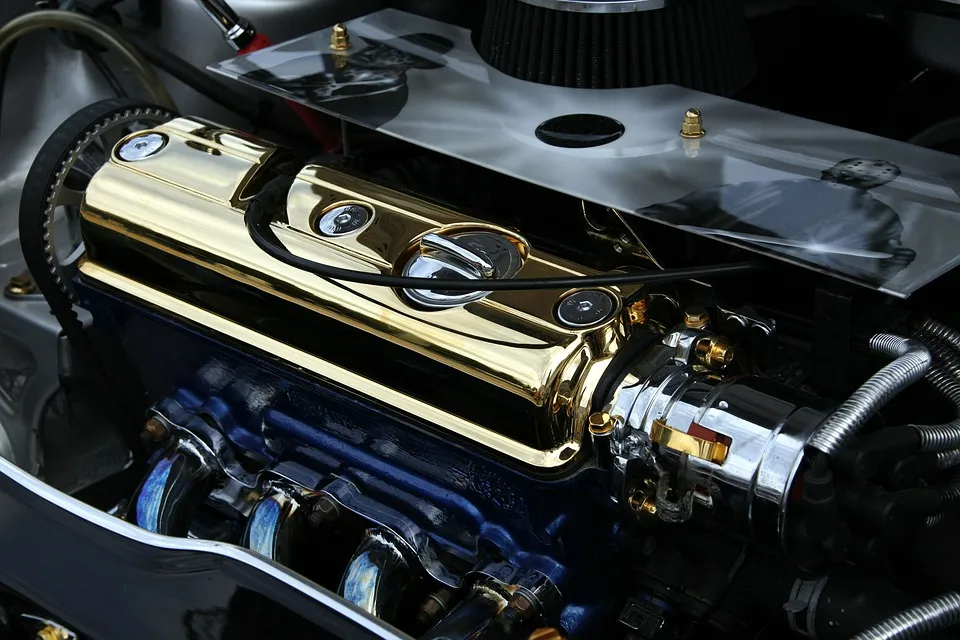

Reversibility

Engines provide us with energy we can use for all kinds of things, and how to optimize them is one of engineering's not so kind central problems. One of the key to solving it is the concept of REVERSIBILITY. The more reversible a system is, the less work it needs from its surroundings. In another word, a more reversible system needs less fuel to keep going. So if you are trying to build the best engine you can, reversibility is a good place to start.

Engines drive our society in many of the machines we use every day. And inside many of our engines are pistons. Piston is a disc or cylindrical part in a back of a cylinder against liquid or gas. In earlier combustion engine, the pistons are pushed by these expanding gases in the cylinder which turns to shaft the wheel. This turns the repeated linear motion into rotation that helps power the engine.

Source: Pixabay (Public domain - CCO licensed)

When you are dealing with a simple machine or mechanism like a piston, there are two main types of energy you can put into or take out of the system. These are HEAT and WORK. You probably have a good idea of what heat is. Simply put; its thermal energy. It's what you feel when you step out in the sun or stand by fire. In engineering, we define heat with the letter Q, work represented by W is a little more complex. It is especially any type of energy other than heat that crosses into system. One way to measure it is by how much force is being applied to a distance.

Types of work

There are different types of work you are likely to encounter as an engineer. But with all of them, the idea is that by putting work into a system, you can get some work out of it. Usually, in a more useful form.

One type is Pressure Volume Work. This has to do with the expansion and compression of matters. Squeezing a stretch ball is a good example. Despite how much pressure you put to compress the ball, the volume change in volume tells you how much work you are able to achieve. When the stretch ball is expanded, we say the work is negative. This is because it is being done by the ball. When it is compressed, the work is positive because the work is being done on the ball.

This involves Pressure Volume Work too. In this example, the work done on a piston comes in a fuel which heats up gas in the cylinder when it is ignited. As the gas expand, it does work with the increased pressure pushing the piston up. Then the gas cools again and the piston moves down. This cycle produces work that tends the shaft to wheel.

Another type of work is Shaft Work. The shaft or propeller rotates through liquid or gas. There is also Electrical Work which is the work done on a charged particle by an electric field. You can think of it like a discharge from a battery. As you reading this post, there is an electrical work going on in your phone or computer.

A lot of engineering is about optimizing your machines and processes to produce the most amount of work with as little input as possible.

The more work a machine uses up, the more you need to get out of it to have a big worth of your work. It's like a job. The more time and effort you put in, the more you want to get paid. That is how work is..well, work. With machines, optimizing work is all about reversibility. You never get more out of the system than what is pertaining to it. That would violate conservation of energy. But if a process is reversible, that means it can go back to its initial state and start over with no additional input. In another word, when a process if reversible, you maximize the amount of work you get from your input.

Irreversibility

Reversible processes are impossible in real life. They require slow, steady, incredible small changes to make sure you don't permanently change the system in a way that you can't reverse without putting some additional work in.

That is something that will require an infinite amount of time. So in the real world, all processes involving work are IRREVERSIBLE. They can be reset to some extent but you do need to put in a bit of effort to get in there. A reversible process is more like the best case scenario; one you can get close to but never actually reach. In engineering, it is not so much about whether a process is reversible but how reversible it is. The closer you can get to reversibility, the more efficient and optimal the process will be.

Source: Pixabay (Public domain - CCO licensed)

To see what I mean, let's go back to that piston. You have the piston to move up and down in the cylinder to a point where it can generate power. There is also a gas in the cylinder. When the piston is up, it expands the gas and pushing it down compresses the gas. When a gas is on the compression, it will expand on its own. But it will compress again unless force is applied to it. It is like the stretch ball, after you squeeze it, it will expand back to its original size but the ball will randomly crumble back on itself without an outside force.

As the piston is designed, the force compressing the piston comes from a brick. When you remove the brickk, the gas in the piston will expand freely and the piston will rise. So, to get the gas to compress again and the piston to go back down, you need to lift the brick to put it back on top of the piston. Since the piston needs outside work to get it back to where it was with the gas compressed, this process is irreversible.

Next, let's say you are trying to break the brick into two. The system stalls down like before with the gas compressed by the weight of the full brick. Then you remove one half brick leaving it right where the piston was near the bottom of the cylinder, the gas still expands but it doesn't put the piston as far since there is still half the brick worth of weight holding it down. The you remove the other half brick and like the first one, you leave it at the same height let's say on a shelf right next to the piston or something, this allows the gas to expand as much as it did when you were using one brick, pushing the piston all the way out.

But think about the amount of time it will take to reverse this process and get the piston to go back down before you lift the entire brick from all the way from where the piston started to where it stops when the gas is done expanding. But this time, half of the brick is already part of the weight in the cylinder because that is where you removed it. So you start by lifting the half brick up to the top which compresses the gas and pushes the piston part of the way down. Then, you lift the other half brick to where the piston is now pushing the piston down all the way back to where it started.

So instead of having to lift the whole brick off the piston, now you effectively only have to lift half of the brick off the piston. It's just a two steps instead of one. That is a much less work which means the process is that much less irreversible than it was with one brick. And now you can start problem solving as an engineer.

If breaking the brick into two makes the process more reversible, how can you make it even better?

A simpler process to keep breaking the brick into smaller and smaller pieces. Eventually you turn it into infinite tiny grain of sand. This time it starts with the pile of sand with the same weight as the full brick pushing the piston down. Then you remove one grain of sand this time leaving each grain at the same height that the piston was when you removed. Gradually, the piston rises, producing work.

But each movement is so small to reverse the process and move the piston down, all you really have to do is shift each grain of sand sideways. Remember we are talking about increments that are infinitely small, so effectively uplifting anything. You can keep shifting the grains of sand sideways and slowly and the weight on the piston will increase, compressing the gas and bringing you right back at where you started which is definitely less work that lifting the whole brick or even a half brick. In fact, apart from that one grain you lifted from the bottom to the top, the amount of work required to put each grain of sand back on the piston is exactly the same as the work produced when you take it off.

Everything is happening so slowly and gradually that you aren't loosing energy as heat, which means that you don't need to add work to replace that lost energy. You don't need to put in any external work to put the piston back down and you can use the same amount of work produced by the system to get it right back to where it started. Then you have it - a reversible process.

Again, this will be pretty much impossible to accomplish in real life. For one thing, you can't actually have infinitely tiny grain of sand. Even a single molecule isn't infinitely tiny. Piston needs an infinite amount of time to get through all these infinitely small steps. So, as you break the brick into smaller and smaller pieces, you can get closer and closer.

It is also worth noting that the closer you get to the reversible version of this process, the longer it will take, which will not be useful for most applications. If this type of piston is used on your car, you will be better off be walking. So reversibility sounds good, but you need to work with irreversible systems if you really want to achieve something. As an engineer, the goal is to figure out how close you can get a system to being reversible while still keeping the time effort and cost effective. This brings us to EFFICIENCY.

Efficiency

In general, the efficiency of any system is the ratio of what you get out of it compared to what you have to put into it. It is going to have a value ranging from 0% to 100%, with 100% being maximum efficiency.

In this case, efficiency helps quantify how close a system is to perfectly reversible. It is the amount of work produced by the system you are looking at as a percentage of the amount of work that will be produced by the ideal but impossible reversible system. The result is ETA, the efficiency. If something ishundred percent efficient, that means it is a complete reversible system. If it has zero efficiency, it is totally irreversible.

You can understand how important efficiency is by going back to cars and engines. The more efficiency your vehicle is, the more energy you can get out of your fuel and the farther you can on a tank of gas. That is why you want to keep efficiency relatively high in most engineering systems. It is especially important whenever you want to sustain a process for a long time, like a cross-country road trip. But sometimes you need to sacrifice efficiency to accomplish your goals. You might need to put a lot of work into a system to do something quickly or get a big output. Converting between types of energy might also be more important than getting a big output of your input.