Selection of Wells with High Permeability Candidates for Fracking

Fracking has been a very successful technique in the stimulation of wells with low permeability. Technological advances have been able to provide many options for optimization of the fractures and thus obtain a better performance in the production of the wells.

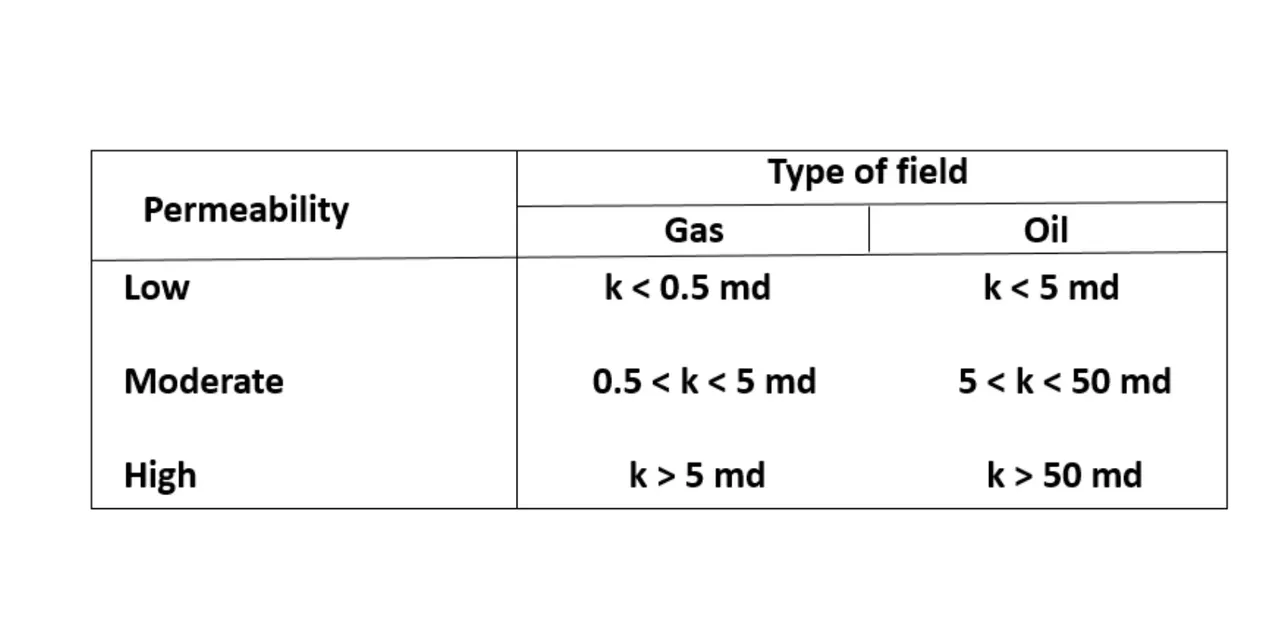

These studies have reached, in recent years, design technologies to be able to apply the fracking in high permeability reservoirs using the technique of fracturing and packing, also called frac-pack. The range of permeabilities considered for the fracture is presented in the following table:

Permeability values considered in fracking

The principle of a hydraulic fracture in a well is to make the formation fail, creating a rupture caused by the injection of a fluid. The propagation of the fracture in the formation it achieves while it continues injecting said fluid to high expenses. The pressure needed to start the Rupture is considered much greater than that necessary to propagate the fracture created. Then, at some point during the injection, a supporting agent is added to the fluid that will keep the fracture open. Thus, a conductive path is created for the flow of fluids from deposit to the well.

Unlike a traditional fracture in low permeabilities, in a treatment of fracturing and packing (frac-pack) very long and short fractures are created. The Fracture length is usually equal to or less than 50 feet, and the fracture width is 1 to 2 inches. Fractures after being propped up operate as conductive channels that facilitate the recovery of reservoir fluids and reduce pressure drops. He proppant that is packed inside the annular section prevents the migration of fines to the water well. In other words, sand control increased production, and longevity of the Reservoir is the center of all frac-pack treatment.

Source

Typical fracture of a frac-pack treatment

The technique of frac-pack to create a fracture that will later be propped up in pumping a free fracturing fluid of suspending agents known as "volume of the mattress ", followed by a fluid known as" grout "(this fluid contains concentrations of proppant). The mattress fluid will eventually seep into the reservoir due to the loss of fluid. This loss of fluid will dehydrate the grout causing low areas pressure that will restrict the spread of the fracture. As a result, the fracture will be propped up gradually from its ends to the well, and until the fracture, width is obtained optimum.

Source

The key to fracturing in high permeabilities is the tip-screenout (TSO) technique, which is a procedure in which the lateral growth of the fractures stops to be able to later "Inflate" them and sustain them with the necessary proppant, resulting in the type of fracture mentioned above. In addition to the improvement of production, there are many reasons to carry out the fracturing in high permeability reservoirs such as:

- Exceed the damaged area between the well and the production área

- Control sand deconsolidation

- Reduce the deposition of fines and asphaltenes during production

- Avoid conification of water

- Improve communication between the deposit and the well

- Match the distribution of flow over large producer intervals

For more information, you can consult the following links

- https://www.slb.com/~/media/Files/resources/mearr/num8/37_49.pdf

- http://petrowiki.org/Fracturing_high-permeability_formations

- http://www.ogj.com/articles/print/volume-98/issue-14/in-this-issue/production/successful-frac-packs-require-careful-planning.html