''An Optimization Machine for Cassava Products Production (Combined Cassava Peeler and Grating Machine)''

INTRODUCTION

Background of the Study

Cassava is the third most important crop plant in the tropics, after rice and maize. It is a long tuberous starchy root, rich in carbohydrates. The root has a brown fibrous skin and snowy white flesh. Cassava is mainly cultivated in the tropical part of Africa, Asia, and Latin America.

This crop is endowed with a unique capacity to contribute to the development of food security and poverty alleviation. The root crop is used as raw materials in making starch, cassava cake, cassava ball, ‘’pitchi-pitchi’’ and other dainties which essential ingredients are grated cassava.

Cassava is the most perishable of roots and tubers and can deteriorate within two or three days after harvesting. It cannot be stored for long because they rot within 3-4 days of harvest. Therefore, cassava must be processed into various forms to increase the shelf life of the products, improve palatability, reduce food losses and stabilizes seasonal fluctuations in the supply of the crop.

The production of cassava crops in the world is increasing as well as the demand, and this trend is expected to continue with the increase in population. It was revealed that cassava peeling and the grating is still primarily done manually; however, women and teenage girls are usually involved in the manual peeling and grating of the tuber. The rate of peeling could be as 350 kg/day of 8 hours/person. A skilled person can grate between 18 – 23 kg/h using a galvanized metal sheet with nail-punched holes. The process is slow, labor-intensive, and time-consuming which leads to low productivity.

Several cassava producers encounter various challenges in cassava processing. Some of this factors include lack of efficient equipment; appropriate processing techniques, machines, and tools. Almost all the processing of cassava requires the roots to be peeled at one stage, or another, and no efficient peeler is on the market (Kolawole et al., 2010).

The first operation performed after cassava tuber have been harvested is peeling. Then, sometimes followed by a grating. Most of the time, peeling and grating go together especially in making starch, dainties and other cassava products, which main ingredients is grated cassava crop. Peeling and grating separately is tedious work, which brings pressure of time, money and inconvenience, especially for a person working independently.

More research efforts have been devoted to the development of peeling machines and grating machines by many research institutes and individual researchers. Currently, some peeling mechanisms have been developed. Several other cassava processing had been commercially mechanized successfully. However, cassava peeling and cassava grating remain a severe global challenge to processors of cassava, and there is no existing machine with both ability to peel and grate cassava crop in one session. Today, because of the absence of combined peeling and grating machine in the market, farms and rural areas, and because of low efficiencies and losses, cassava peeling and the grating is still mainly carried out manually. This situation has made it necessary to provide an excellent, efficient and time conserving machine in the reduction of energy expended in carrying out manual peeling and manual grating as well as the time taken in peeling and grating.

Objectives of the study

This study attempted to design and fabricate a Combined Peeler and Grating Machine, determine its performance, and the quality of cassava peeled and grate.

Primarily, the study aimed to:

Design and fabricate a combined peeler and grating machine.

Determine the performance of Combined Peeler and Grating Machine concerning:

2.1 Removed Skin

2.2 Unremoved Skin

2.3 Quality of cassava grated by the machine.Compare the efficiency regarding tuber losses of the Combined Peeler and Grating Machine to the manual operation using a knife in peeling, and using a galvanized metal sheet with nail-punched holes in the grating.

Compare the difference in the amount of cassava peeled and grate using the Combine Peeler and Grating Machine and using the manual operation.

Theoretical/Conceptual Framework of the study

The theoretical basis of this study is the system approach which considers two essential components: elements and process. It integrates the analytical and synthetical methods, encompassing both holism and reduction.

Another theory that serves as bases for the study was stating the relationship among technical knowledge, the manual skills, and job or occupational intelligence. The theory state that efficiency on the job varies or depends upon the possession of the necessary manipulation of powers, the functioning technical knowledge, and information which the individual to apply technical knowledge and the manipulative skills of the problem of the job.

This study focused on the design and fabrication of Combined Peeler and Grating Machine, and physical evaluation of cassava peeled and grate from the machine. The process includes are peeling, washing and grating. The product produced was assessed regarding the following parameters: evaluation of unskinned cassava crops, assessment of skinned cassava crops, which the machine have not removed, and evaluation of the quality of cassava grated from the machine.

The study involved two variables: types and sizes of cassava crop to be used for peeling and grating. The cassava used in the study were the freshly harvested crops.

Significance of the Study

This study is significant to all those who are concerned with the investigation, most especially the following:

Farmers. This will help the farmers to generate more income because the demand for cassava crops in the market will increase.

Entrepreneurs. This will serve as a useful asset for entrepreneurs to help them grow their current business.

Community. The community will benefit a lot from this project. Making cassava products will be more comfortable, and they will gain insights in starting a small business.

Scope and Delimitation of the Study

This study was conducted to design and fabricate the Combined Peeling and Grating Machine. This study delimited to the evaluation of the performance of the combined peeler and grating based on efficiency and its product. The machine applied to a small scale of operation for cassava processing.

Related Literature

Cassava Tuber

Cassava (Manihot esculenta) is a woody shrub perennial plant that belongs to spurge family (Euphorbiaceae). It is extensively cultivated as an annual crop in the tropical and subtropical regions for its edible starchy tuberous root. Cassava is a primary staple food in the developing world, providing a basic diet for over half a billion people. It is one of the most drought-tolerant crops, capable of growing on marginal soils. The mature tubers can be 5-10 cm in diameter and 15-30 cm long when harvested 9-12 months after planting.

The tuber is usually cylindrically tapered which differ in weight sizes and shape. They sometimes white, brown or reddish depending on the variety. It is surrounded by a thin cambium layer covered by peel, which consists of a corky periderm on the outside and cortex on the inside (Adetan et. Al., 2003). The outside periderm may be thick, rough or thin and smooth with surface varying considerably in color from pink to grey (Igbeka,1 984). The three layers of cassava tuber as described by Abdulkadir (2012) are the following:

(i) The periderm – the tuber’s uttermost layer, the peel (rind)

(ii) The cortex – usually about 1.5 to 2.5 mm thick and white in color. This lies below the periderm.

(iii) The central portion of the tuber – mostly composed of stored starch, which is white in color. This makes up the more significant bulk of the cassava tuber.

Cassava Processing

Machines for cassava processing are made to replace the hand-operated method and to increase output to attain the required demand for food, fiber, and materials. Suitable mechanization and automation are vitally needed to achieve the desired end product. Some manual methods like peeling, washing, grating, pressing, pounding, pulverizing and pressing are successfully mechanized with the year of development and modernization.

Peeling

After harvesting and cleaning from debris, peeling is the first operation to perform. Cassava peeling has been practiced as far back as when cassava came into existence.

However, the tools used for peeling has developed from stones and wooden flight into a simple household knife. Cassava must be peeled to remove the inedible outer part of the root consisting of the corky periderm and the cortex (Adetan et al., 2003). These are known to contain most of the toxic cyanogenic glucosides, the ratio of glucosides compared to the starchy flesh varying between 5-10:1. Hence, for a root composed of 15% peel with a total cyanide content of 950 mg/kg (fresh weight basis) and 35 mg/kg in the flesh, 83% of the total cyanide is removed by peeling (Bencini, 1991).

Concept of Peeling

Shown in figure 2 is a cross-sectional image of a tuber consisting a central core called parenchyma or the pith. This is surrounded by the starchy flesh which forms the bulk of the tuber and the primary storage region. The tuber peel which consists of a corky periderm on the outside and cortex on the inside covers the cambium layer. The cortical area is usually white and varies in thickness between 1.2 and 4.15 mm (Adetan et al., 2003). Unlike the other root crops, the peel of fresh cassava crop can easily be removed from root flesh because of the thin cambium layer separating them.

Manual Peeling

Peeling is usually done manually using a knife. In varieties which are easy to peel, the peel is slit along the length of one side of the root, and the knife-blade and fingers are used to roll back the skins from the fleshy portion of the root. With varieties which are difficult to peel, the two layers of peels are whittled with a knife in a motion reminiscent of sharpening a pencil. This operation is less satisfactory as it usually results in the removal of some flesh along with the peels and some of the skins are left on the root.

The manual way of peeling of cassava tubers with knives is usually done by women and teenage girls (Ohwovoriele et al., 1988). The rate could be as high as 350 kg/day of 8 hours/person (Igbeka et al., 1992). Manual processing for commercial purposes requires a minimum of four person-days to peel and wash, and twenty-three person-days to prepare tons of flour (Kolawole et al., 2010). Hand peeling is time-consuming and labor intensive which leads to low productivity. The losses involved in the method are high, and this process is less efficient.

Manual Grating

Hand grating is painful and most tedious work. It requires 10 – 15 worker-days of effort to hand grate one tonne of fresh cassava. The manual grater is usually a piece of galvanized metal sheet or even a piece of tin or can, punched with nails about 3mm diameter leaving a raised jagged flange on the underside. This grating surface is fixed on a wooden frame, and the cassava piece is pressed against the rough side of the metal and rubbed vigorously with strong downward movement. A whole cassava root is not wholly grated using this method. About 3% to 5% cassava has to be left ungrated to protect fingers from the grating. However, power – operated graters of various makes and models are now existing and being used.

Related Studies

An Ni Le's research entitled, ‘’ Pedal Powered Cassava Peeling Machine’’. The machine has a rotating drum which maintains the purpose of rubbing the cassava skin off, using high-tech abrasive rollers with wire brushes. The testing has shown that the machine has a capacity of peeling 60-100kg/h (compared to 20-35kg/h peeling by hand), with an average flesh loss of 5% (compare to 25% peeling by hand), average peeling efficiency of 95%.

Oluwole and Adios in their studies entitled, ‘’Cassava Peeling machine’'. The method used is a mechanized means of peeling the tubers and uses devised mechanisms. It has a principle of abrasive peeling using a stationary outer abrasive drum and a rotating inner abrasive drum based on a batch capacity of 8.5 kg and cut tuber lengths of 200mm and diameters of 90mm. An average peeling efficiency recorded was 70.45 percent while the average flesh loss was 5.09 percent and percentage of broken cassava was estimated to be 2%.

Ugwu K. C. and Ozioko R. E. also conducted a research entitled ‘’ Development and Performance Test of Cassava’’. The result of their study showed that the feed rates used on the machine do not show any significant variation in the machine efficiency, and the throughput capacity does not influence the effectiveness of the device negatively. It was found that the irregular or indistinct shape or size of cassava tuber hindered the efficiency of the machine. The result obtained showed that the machine performance was 72 % at a speed of 420 rpm.

Ndaliman’s research entitled, ‘’ Design and Construction of a Pedal Operated Cassava Grinder’’ described a pedal operated cassava grinder which is powered by human efforts applied to the pedal. The grinder pulverizes the cassava tubers into a paste which can pass through a wine sieve. The efficient performance of the design was at 60%.

Oyesola also conducted a study entitled, ‘’Technology Processing Cassava and Utilization’’ reported that the traditional method of grating involves placing of the local grater, which is made of a perforated metal sheet on the table where it is convenient for efficient use and brushes sheet metal. The cassava turns into pulp and drops into a container that is being used to collect the grated pulp cassava.

The related literature and studies mentioned in this chapter enhanced the researcher’s insights into the variables included in the design, fabrication, and performance of the Combined Peeler and Grating Machine.

METHODOLOGY

To be able to achieve effectiveness, the acceptability of the machine during operation and testing, the machine had undergone considerations for designing that fits the requirements of the desired output for processing cassava commodity.

Machine system

The machine should confirm the following factors;

1.The machine should be designed ergonomically for safer and convenient operation.

The machine shall have a proper procedure, material selection and waste discharge mechanism must be used.

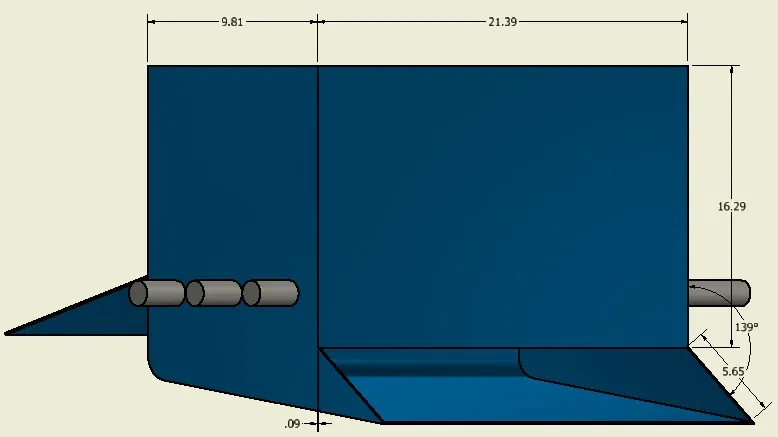

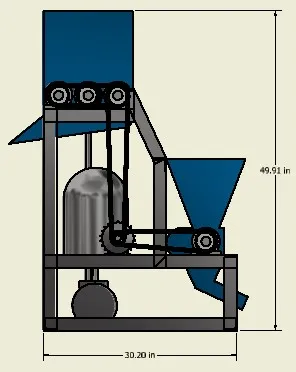

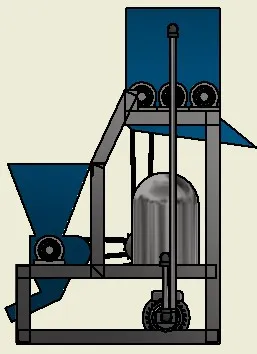

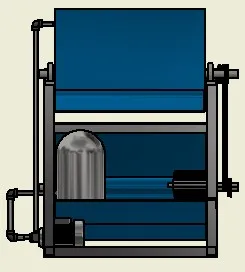

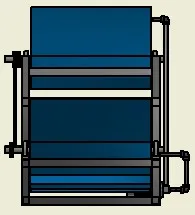

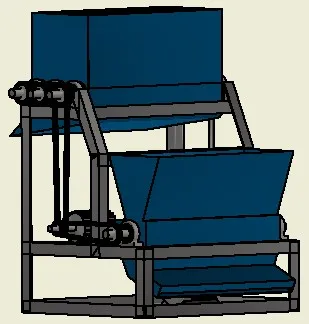

Peeling Mechanism

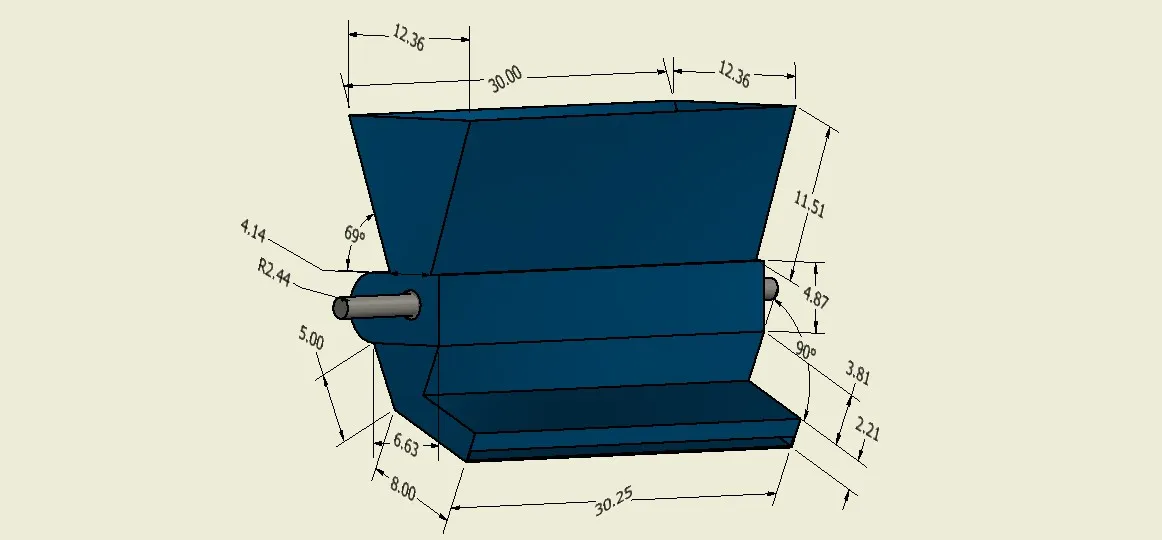

The design is batch type peeling where the cassava tuber is feed above a rectangular container with peeler blades located at the bottom. The blades are like long slanting thin strips attached to a manufactured cylindrical metal which is connected to a shaft. The purpose of these flat strip blades is to ensure that percent loses on the tuber is prevented or minimized. The machine has three (3) rotational peeler blades, which is horizontally connected and parallel with each other. When cassava tubers were dropped into the peeling machine, it creates contact with the blades allowing cassava crops to be peeled. During peeling, the machine adds water for washing and cleaning the tubers with the used of a water pump and sprinkler type water storage, positioned above the peeler machine. Below the rotational blades, a chute is found wherein the cassava peel wastes discharges. As the circular blades rotate, cassava tubers move closer to the peeler wall, which opens and closed manually. The wall serves as the pathway of unskinned cassava crops to be transferred to the grating machine for the grating process.

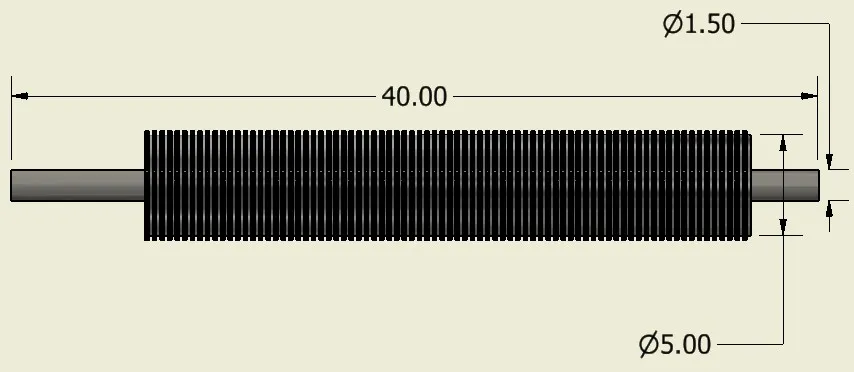

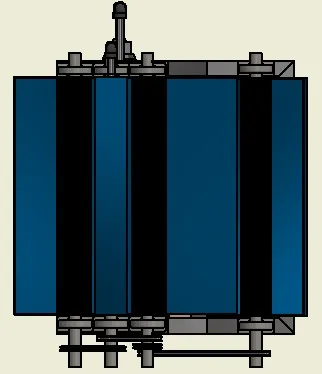

Grating Mechanism

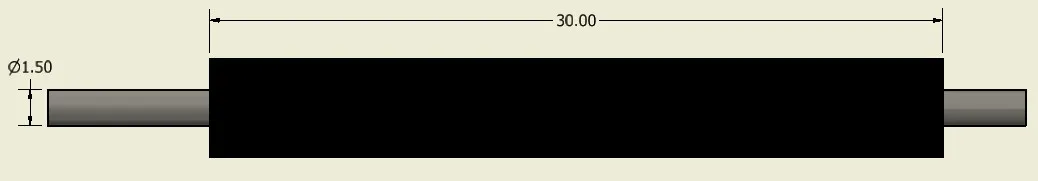

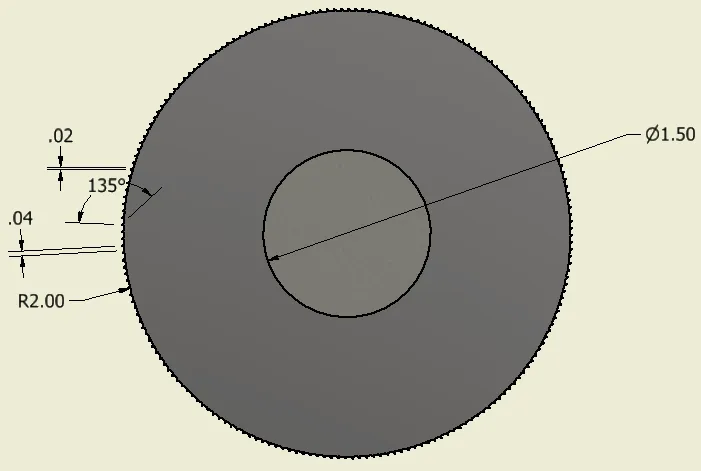

This unit is composed of teeth slightly sharpened in both edges. (See figure). The teeth are attached to a manufactured cylindrical metal, which is power transmitted by a shaft. The grated cassava pass through the cylinder to the chute of exist.

Physical Design

The researchers used Autodesk Inventor to create two and three-dimensional drawing for effective change and adjust drawings using the software and shown in figures below.

Materials

Materials selection is the most critical factor to consider in constructing any machines since its elements must have an appropriate choice to perform well and achieve the required performance output. The material should be free from any physical and chemical reactions such as corrosions and contaminations.

Machine Frame

The frame must be rigid that it can sustain static and dynamic loading. Its role is to provide balance from the applied stress. Angular medium carbon steel can be used as frames.

Peeling Blades

The peeling blades are made of a stainless metal sheet to prevent corrosion and contamination.

Peeler and Grating Casing

Both this two casings are made by stainless metal sheet since it will always in contact with the cassava tubers.

Chutes

The chute is also materialized by stainless metal sheet to avoid chemical and physical reactions for in coming years.

Grater

This is made with stainless steel. It is cylindrical shape teeth slightly sharpened at both ends to facilitate grating and connected with a shaft of the motor.

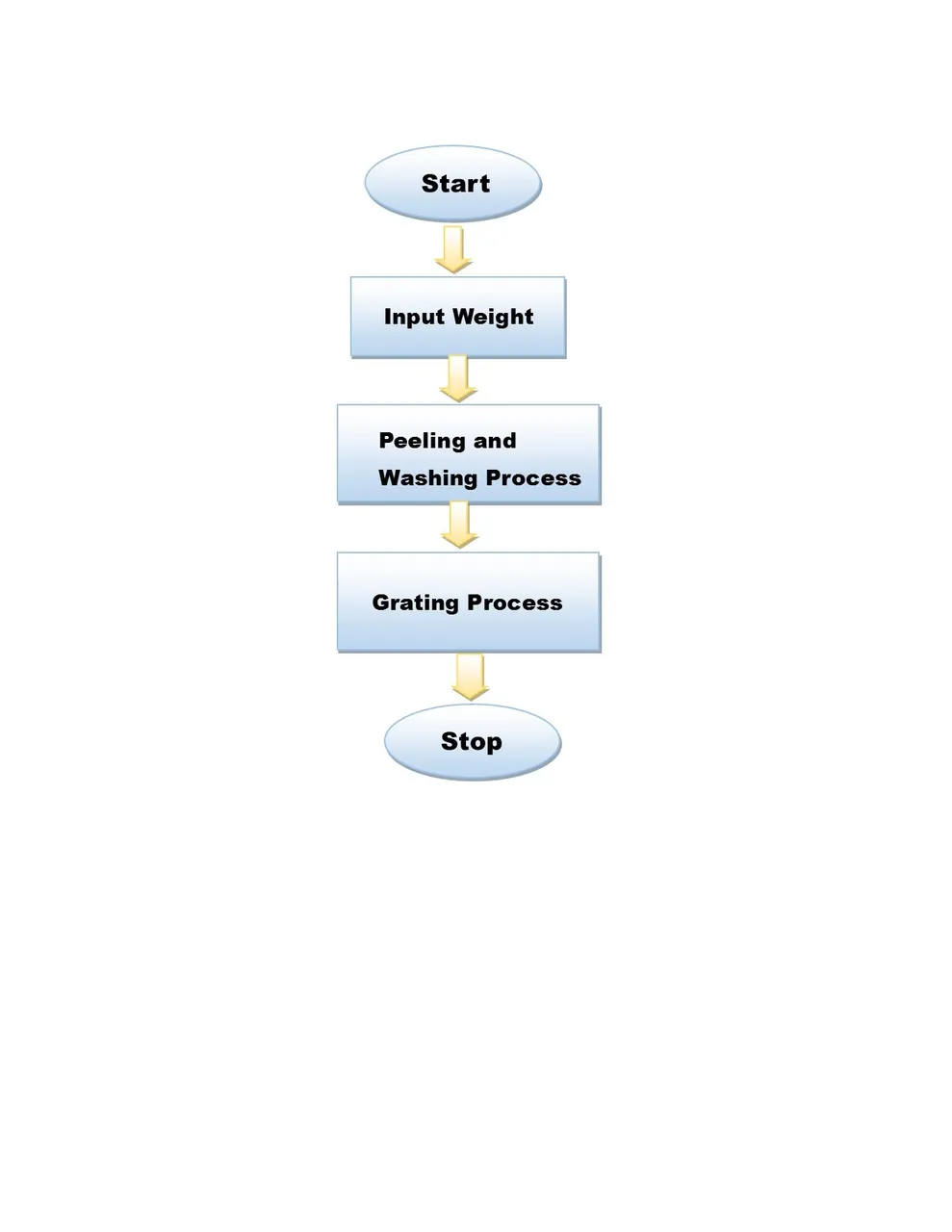

Operational Block Diagram

This is an ongoing project, if you have any suggestion or recommendation, don't hesitate to comment below. Thank you so much! I need your help for this project; your upvote is very much appreciated.

Best regards: @Lymierikxz

References:

Adetan, D.A., L. O. Adekoya, & O. B. Aluko (2003).Characterization of some properties of cassava root tubers. Journal of Food Engineering, 59, 349-353.

Abdulkadir, B. H. (2012). Design and fabrication of a cassava peeling machine. International Organization on Scientific Research (IOSR).Journal of Engineering (IOSRJEN), 2(6); 01-08.

Bencini, M.C. (1991). Post-harvest and processing technologies of African staple foods: a technical compendium. Agriculture Services bulletin No. 89, FAO, Rome

Ohwovoriole, E.N., Oboli, S. & Mgbeke, A.C. (1988). Studies and preliminary design for a cassava tuber peeling machine. Transactions of the American Society of Agricultural Engineers (ASAE), 31(2) 380-385.

Igbeka, J.C. (1984). Some mechanical and rheological properties of yam and cassava. African Journal of Science and Technology, 3(2); 45-60.

Kolawole, O.P., Agbetoye, L.A.S. & Ogunlowo, A.S. (2010) .Sustaining world food security with improved cassava processing technologies: The Nigerian Experience on

Sustainability, 2; 3681- 3694.

"Cassava". Food and Agriculture Organization of the United Nations., https://en.wikipedia.org

Cassava, http://www.newworldencyclopedia.org/entry/Cassava

S.K. Hahn., An overview of traditional processing and utilization of cassava in Africa, http://www.fao.org/wairdocs/ilri/x5458e/x5458e05.htm

Major Vegetables and Root crops Quarterly Bulletin, April-June 2017., https://psa.gov.ph/vegetable-root-crops-main/cassava

Jimoh M.O.,‘’An Automated Cassava Peeling System for the Enhancement of Food Security’’, http://www.sciencedirect.com/science/article/pii/S0189724115300382

Processing of Roots and Tubers, http://www.fao.org/docrep/x5415e/x5415e05.htm

Kolawole, O.P., Agbetoye, L.A.S. & Ogunlowo, A.S. (2010) .Sustaining world food security with improved cassava processing technologies: The Nigerian Experience on Sustainability, 2; 3681- 3694.

YOU CAN ALSO READ MY PREVIOUS ARTICLES: