This particular casting run provides some valuable information needed to improve the general process. Granted, my setup is somewhat limited at the moment, so not every alternative method is open to me - you'll see what I mean in a later post.

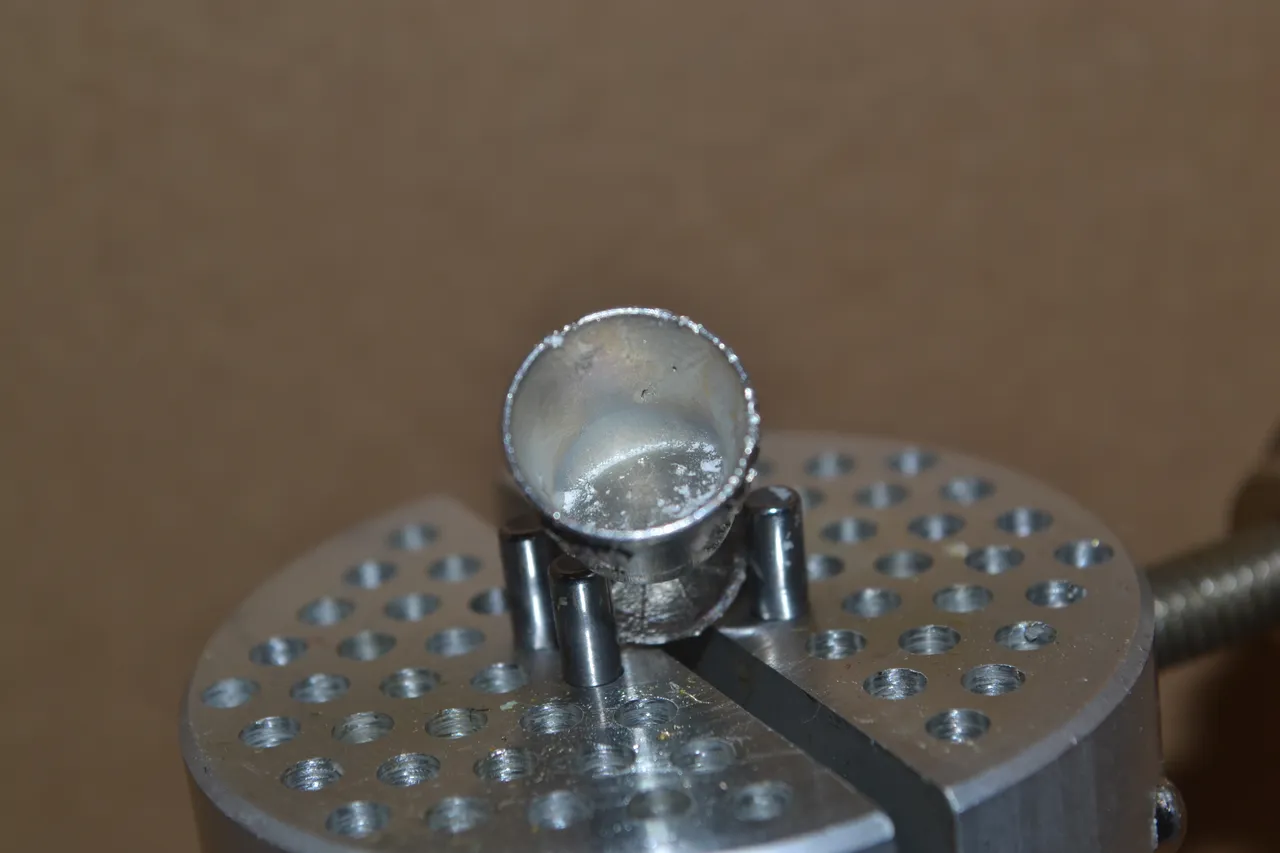

Because this was cast at a fairly low temperature, with the mould held at 300 degrees immediately prior to pouring. As a result, when the mould was quenched, it didn't shatter, but instead bubbled quite a lot. I still had to dig a bit to free the casting. The cone at the top fell off almost immediately, so by the time I brought the casting inside to take better pictures, this is what was left:

This casting is far from perfect, so I'll explain what needs to change, at least for these particular items.

Tiny spheres stuck to the casting indicate that there were still bubbles in the investment, so it needs to be more thoroughly de-gassed. I'll just leave it in the vacuum chamber longer next time. Furthermore, while I mentioned in my last post that I tipped the part tree to try freeing trapped air from inside the cups, it obviously didn't work:

The only reason they were pointed down in the first place was because there wasn't room to have them sideways. The chaos chalice was by far the worst in this regard:

Sometimes, the symbol came out nice and clean, but sometimes they have major surface flaws, such as voids. The flash on my camera doesn't show this all that well, but maybe you can make out what I'm talking about.

The most important thing I need to do, at least with tin, is to build a slag trap. The zipper pull acted as a slag trap during this particular casting, with all the nasty stuff getting stuck in the main body, while the loop came out perfectly - you can even see the print lines!

I will keep these castings for now, and in my next run, I'll use the tin left over from this run, which I poured into an ingot mould:

I'll try the mushroom next. If it goes well, I'll move on to bronze. Assuming I can ever upload anything to BitChute again, perhaps you'll see a video of the process.