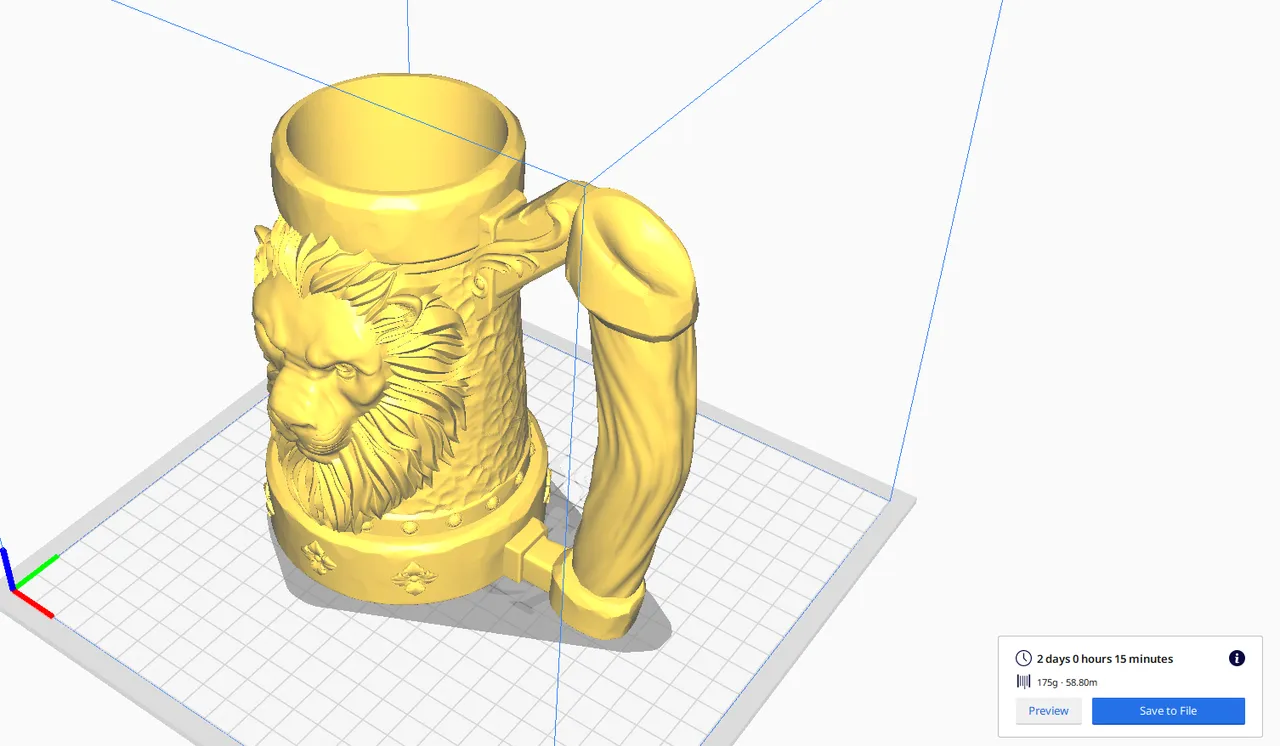

A buddy of mine challenged me to make a 3D print of this, then cast it in metal. I looked at the full size mug, and thought that was a bit much. I mean...look at this!

2 days to print something that I don't even know if it'll work? Yikes... So I decided I'd start smaller. I'd make a shotglass instead! I basically just scaled it down, and told the printer to do the rest. The print came out fine, and I made a mold in plaster for the print. I put it in my oven for half a day at 500°F, and all the plastic melted out, leaving a nice void behind:

The handle is there, it just has a layer of plaster that isn't showing up in here. That's fine. So I just got done pouring the molten aluminum into it, and, well...

It was kind of a failure. I figured out why, though. I didn't properly heat up the mold enough, so metal solidified before it could fill all the voids.

This is especially prevalent on the backside of the mug.

But that detail in the lion is just gorgeous!

I also noticed something else. I need to make sure that I use less sand in the plaster/sand mixture. I might also need to sift out some of the larger rocks. That's part of why the top looks better than the bottom. All the big rock pieces settled at the bottom of the mold while it solidified. Knowing what I know now, though, I'm ready to try again! And I can just reuse the same metal!