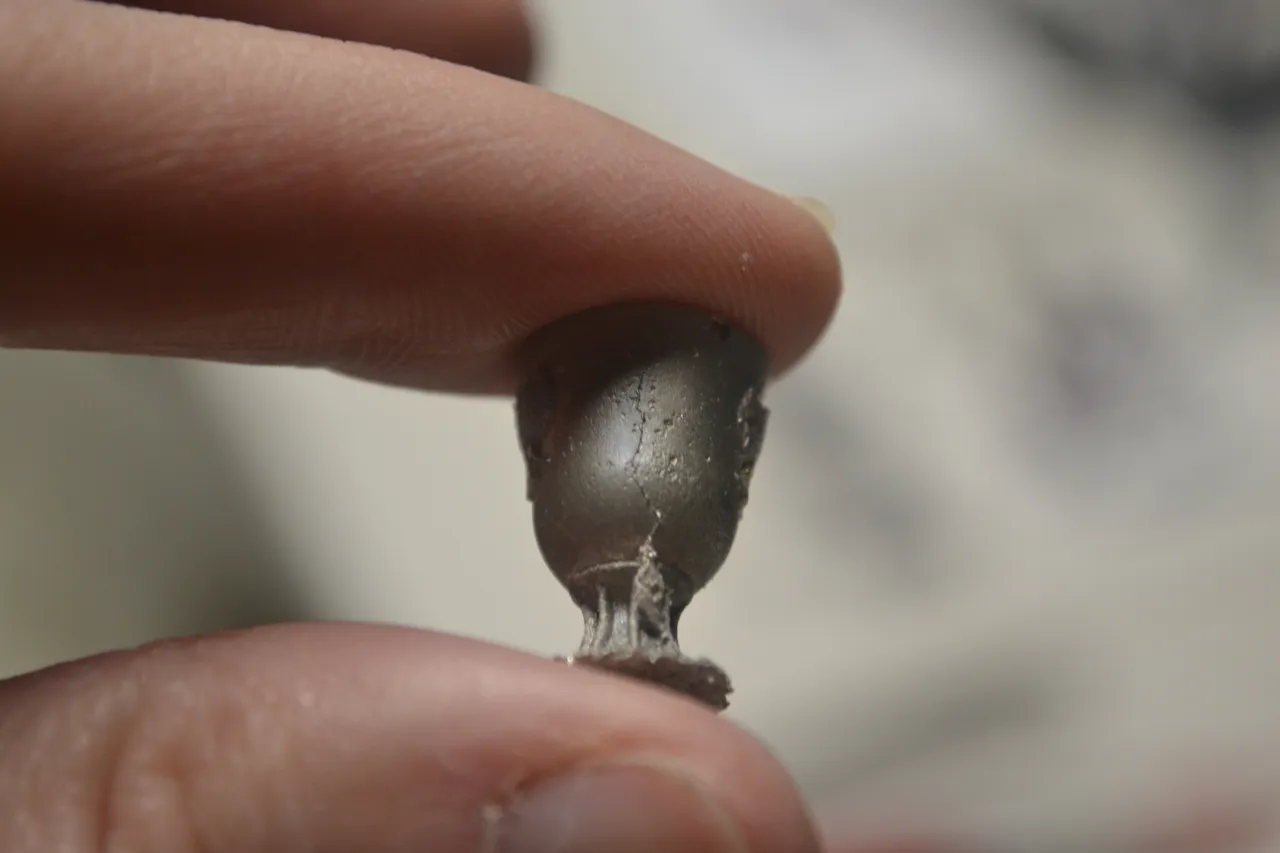

This looks a good bit worse than the last one, doesn't it?

The excess metal, called "flash," is the result of cracks in the mould (or from a mould seam, as the term is usually applied). As I had feared, even a small mould cannot be heated too quickly. Therefore, I'll be stuck babysitting my non-programmable kiln and ramping the temperature manually, increasing it by 40 degrees every ten minutes, leaving it alone only during the two-hour hold periods. That's what I did the first two times, and it worked.

Luckily, at least the new process for making the mould seems to be an improvement. There were far fewer bubbles, owing to the longer de-gassing cycle.

The line running up the side of the cup is from a very shallow surface crack in the mould. Honestly, this was the result I was expecting the first time, when I used ordinary plaster to make the mould (and ramped up the temperature the way I was supposed to). Oh well, live and learn!

Thanks to the new orientation of the cup, the bottom isn't filled with metal. There is one moderately-sized bubble in the bottom (no idea why that's there), and the only other complaint that I have is that I'm still getting voids in the walls. This time, it's considerably more noticeable.

The mushroom, meanwhile, came out in two pieces, and a lot of it is missing. I have no idea why, but I'm going to attribute it to the improper burnout cycle. I think I'm going to buy another flask (I can't make one at the moment, but I can once I'm back in my machine shop) so that I can have more than one mould in the works at a time. I can still have multiple part trees under construction, of course. The next part tree will probably be another batch of cups, with a different configuration and a slag trap. If the slag trap works as intended, I'll put one on every future part tree.

Despite my extensive video documentation of these experiments, I don't think I'm going to publish any footage of failed casting runs. After all, my intent here is to figure out on my own what I can get away with before trying to teach anyone else how to do this. Besides, if someone were to ask me "what happens if I don't do [insert procedure here]," I'd like to have an answer.