Researchers from the American National Institute of Standards and Technology (NIST) have created new composite materials - flexible, durable, durable, non-toxic and reflective. But the most interesting thing is that the raw material for its production is an unusual component - wood pulp and dry parts of exotic marine life.

** The materials described by scientists in their recently published report in the edition of Advanced Functional Materials can soon find applications in various fields. It can be a pack for food, medical supplies, construction, transportation and even space exploration. **

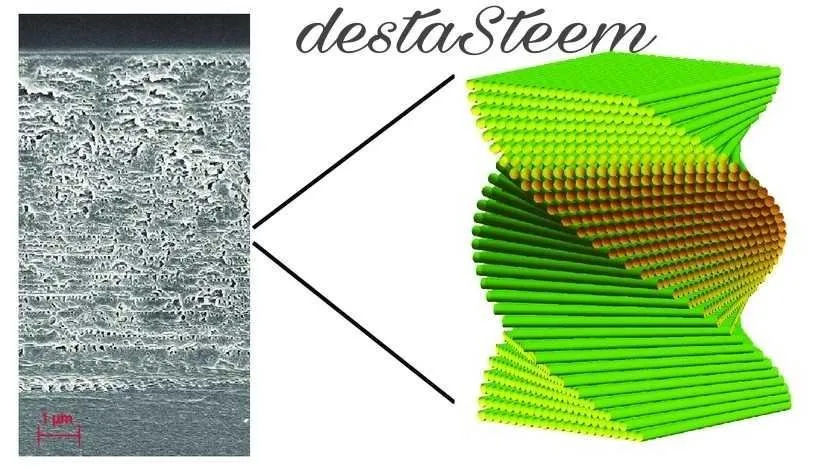

The key to the bizarre environment of wood waste and carnivorous "sea syringe" is the so-called Bouligand structure, where its molecules come in a crooked shape, like a small spiral staircase. This arrangement provides resistance to cracks and breaks - in terms of impact load, the strength is distributed in a number of directions. As a result, parts of the appropriate material remain intact and retain their functional characteristics.

We have artificial materials that are reminiscent of the Buligan structure - these are plywood, where layers are placed perpendicular to each other. If each time stacked with some angular displacement - this would be a Buligan structure model. There are many analogues in the living world, especially on insects, whose coverings and chitinous organs must be very strong.

Wood attracts scientists for decades for its cheapness - large amounts of waste remain in the paper industry and with wood. As a result of various experiments with him, interesting results were obtained several years ago. After washing cellulose with acid to remove the lignin and amorphous fraction thereof, a fixed solution, which at the time of drying forms a new material with a Buligan structure. A key component of this material is a small crystal cellulose rod, called cellulosic nanocrystals or nanocellulose. However, the cellulose material itself is very fragile.

** The NIST team suggests that combining short nanoselulose logs with other natural materials with longer fibers can lead to a promising new material that is lasting, but at the same time flexible. **

One of the second component options is the dry part of the sea syringe ** (Styela clava) ** , which now overflows the world's oceans and is considered a pest. Although in some countries it is eaten gladly.

In many parts of Asia, this brown aquatic creature is considered a delicacy and they wear spicy sauce. They spread from their natural habitats across the world's oceans and pose a threat to local species. Sea syringe populations are rapidly increasing, displacing others, other than disturbing people - they fill the bottom of ships, fishing gear and propellers hammered. When eating plankton, they do not give it to those who have eaten it before.Under favorable conditions, they can grow up to 1500 individuals per square meter!

Finding a way to get rid of this syringe, and even useful for humanity, would be a very useful discovery. Just like oysters, Asians eat the inside of Styela clava, and the outer cover is discarded. Thus, the second component of this composite material also becomes wasteful.

** What is of great interest to NIST researchers, its internal covering structure contains very long nanocrystals. For them it's just a big find. **

After testing different concentrations of the components to be mixed, scientists can determine the exact proportions of the highest strength. This is about 30 percent Styela clava and 70 percent of the pulp. The resulting composite becomes 15-20 times stiffer than that consisting only of cellulose. Further concentration increases do not lead to significant performance improvements.

** Sea syringes are very common, but the processing is relatively expensive, and if scientists find ways to relieve them, then there will be great prospects for the use of new materials. **

The addition of Styela cava shells also alters the process of rotating the nanocellulose, the new sample becomes more dense, which gives it a reflective effect of ultraviolet. This new property can allow new materials to be used as a protective coating, as many fear substances of sunlight.

In the coming years, the NIST team intends to continue experimenting with new composite materials, improving technology and production characteristics, and looking for areas of commercial applications.