Reasons for my absence in Posts will become apparent below. My van conversion has progressed in giant leaps as I have spent quite a bit of planning, consideration and time putting some bulk into the build. This is PICTURE heavy, so I'll let most of the pictures do the talking.

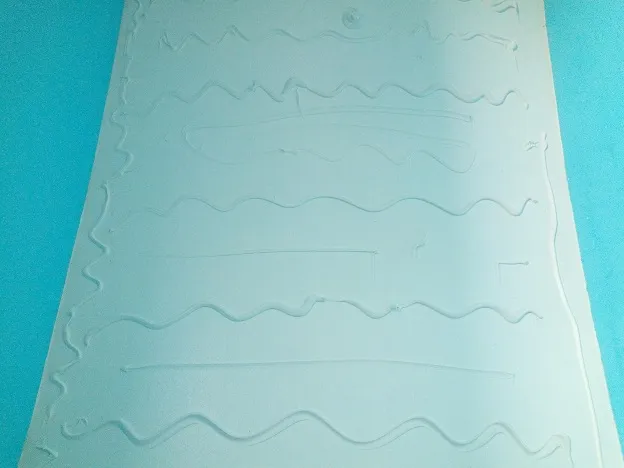

Below = just about to glue the hygienic PVC cladding for the shower cubicle. 'You can never have enough glue!'

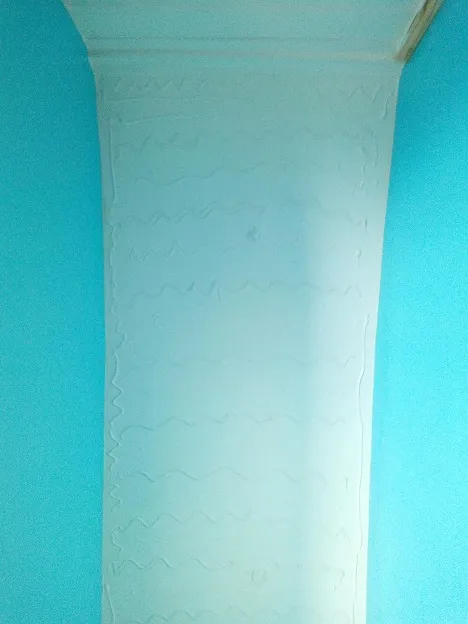

PVC shower walls installed and sealed - Blue plastic film about to be peeled off.

Shower curtain up!

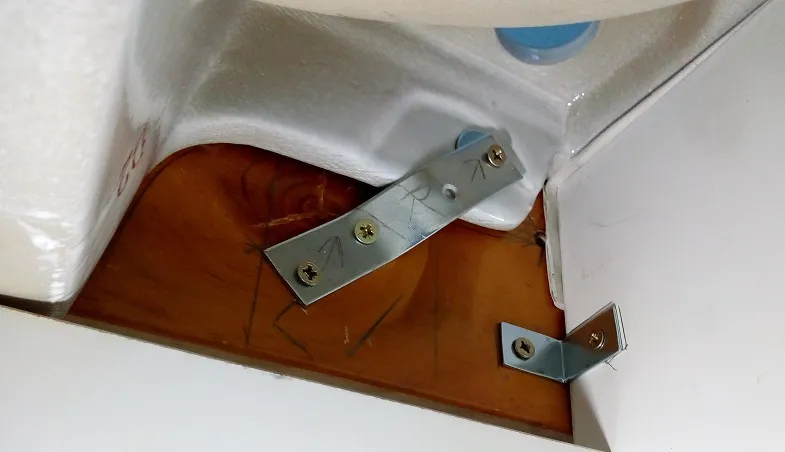

The Vanity Unit

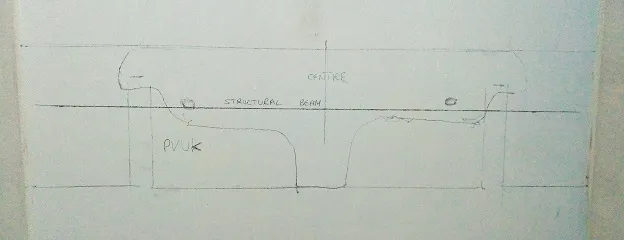

This is a standard vanity unit and sink. Made of porcelain, it is quite heavy and so required a robust installation approach, hence I made some custom brackets.

Some workings out!

In a moving and vibrating vehicle, everything requires secure fixings to the wall.

No exceptions.

DONE!

The Kitchen Units & Sink

A 1ft cupboard and 3ft sink unit - A variety of supplied fixings, dowels and screws.

The Kitchen Work Surface & Sink

I used a long and flat piece of 12mm wood (shop bought) as it is lightweight and easy to work with.

Thanks for dropping by folks... Questions, queries and comments below please (I am no DIY expert lol)!

Van-build stages:

My Latest Brainwave & Project

Assessing The Task

The Strip Out

Floor Preparation & Rust Treatment

Hole Plugging & Lock mending

Finalising The Floor Foundations

The Insulation Begins

Insulating The Floor

Wall Insulation

The Bed & Test Run

Replacing The Windscreen

Building The Bathroom Walls